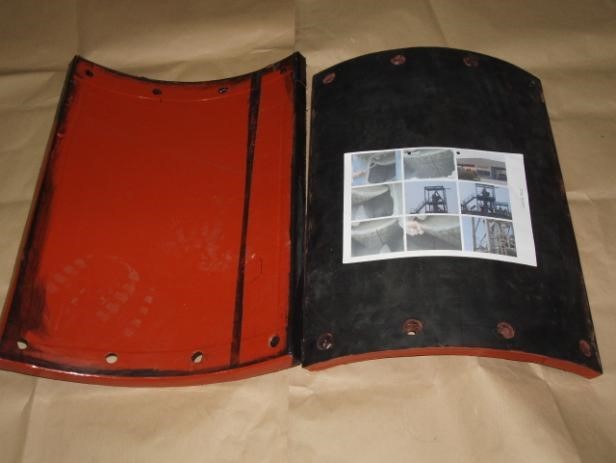

In any of our pulley rubber lagging job, we strive on:

- Improving the frictional resistance between the conveyor belt and the metallic surface of the pulley.

- Optimizing wear protection and force transmission.

- Improving the frictional coefficient to almost 2x compared to pulleys with no rubber lagging.

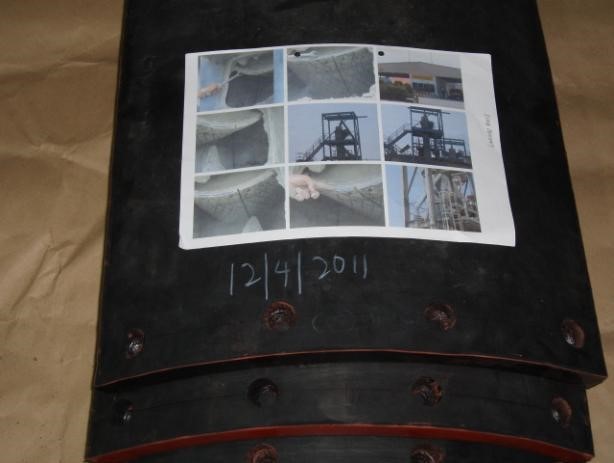

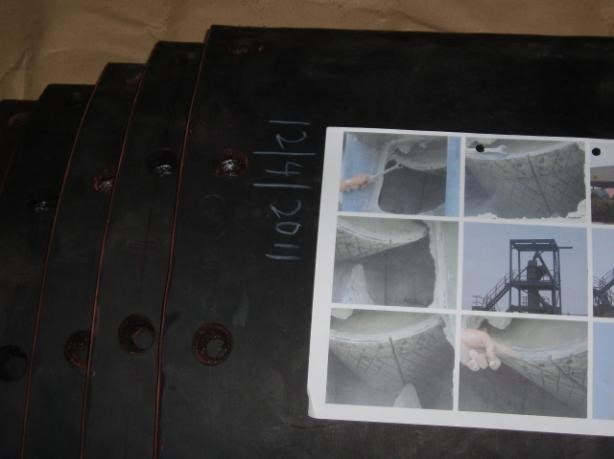

Our solution comes with warranty and we are happy that some of our customers’ belts have outlasted the warranty period. The warranty goes up to 10 years, subject to the lagging methodology and your belt application. The main pulley rubber lagging services that we provide and their warranty are described in the sub-sections below.

For other application belts such as heat-resistant, chemical-use or steel colt belt, please send us a message by clicking here and we shall advise on the warranty period applicable after taking into account the application as well as the belt specifications.