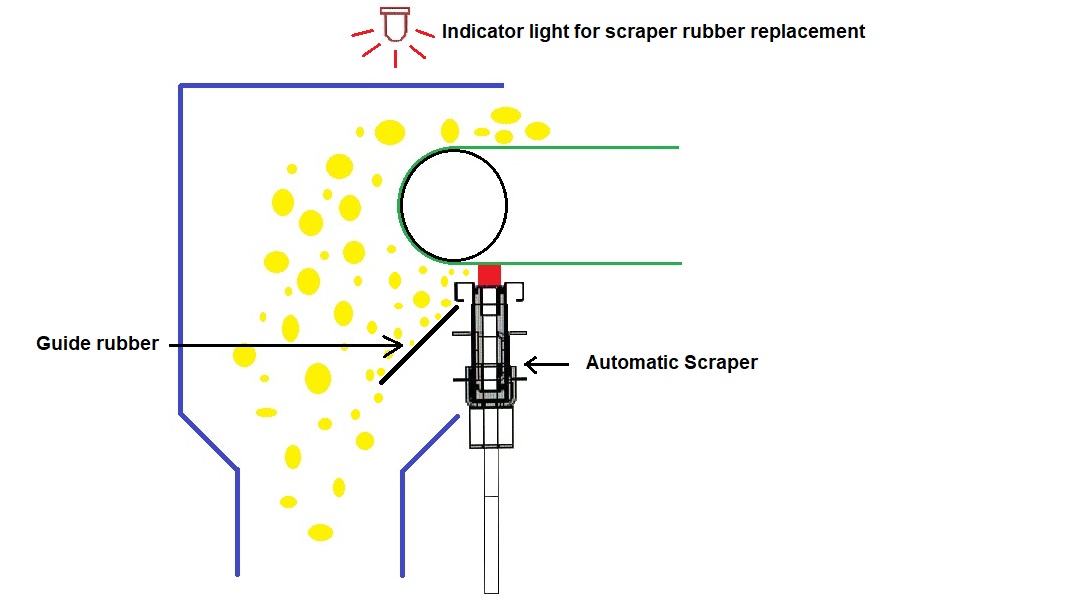

AIM Automatic Scraper

In typical conveyor belt system, all sticky materials will remain on the conveyor belt return side. This causes the return rollers to be caking, and subsequently increase the chances of the belt to be misaligned. This snowball effect ultimately result in the belt being cut by the conveyor structure. Knowing that conveyor belt is expensive, all users will want to eliminate this problem.

As such, scraper is being implemented. Many scrapers are available in the market by now but many exhibit an undesirable trait – they are likely to damage the belt while it performs its scrapping function.

Years of working with our customers and investigated these kind of cases, Aim Precision Engineering designed and developed our own scraper which will not cut nor damage your belts. AIM Automatic Scraper applies appropriate working pressure that perform its job sufficiently, yet does not introduce additional, unnecessary pressure on the conveyor belt.